Advanced Solutions for Storing Hydrogen Safely: The Future of Industrial Energy Storage

Industrial hydrogen storage represents a critical challenge for the energy transition. According to the International Energy Agency’s 2024 Global Hydrogen Review, hydrogen storage capacity must increase tenfold by 2030 to meet decarbonization targets. But how can industries safely store massive quantities of hydrogen while maintaining operational efficiency? explore vallourec for innovative hydrogen storage solutions that combine proven engineering with modular scalability.

Critical Safety Protocols in Large-Scale Hydrogen Storage Operations

Large-scale hydrogen storage operations demand rigorous safety protocols that go far beyond standard industrial practices. The inherent properties of hydrogen—its low ignition energy and wide flammability range—require comprehensive risk management strategies backed by continuous monitoring and fail-safe systems.

Topic to read : Key components for designing custom mobile apps for uk retail businesses

Modern storage facilities implement multi-layered detection systems that monitor hydrogen concentrations in real-time, with automated ventilation responses triggered at predetermined thresholds. These systems undergo extensive validation through third-party testing, ensuring compliance with international standards including ISO 14687 and ASME Section VIII specifications for pressure vessel design.

Material selection represents another critical safety dimension. Advanced steel tubing systems must demonstrate resistance to hydrogen embrittlement through accelerated testing protocols that simulate decades of operational stress. The certification process involves both laboratory testing and field validation, with proven technology demonstrators serving as benchmarks for commercial deployment.

Also to read : Essential tactics for uk construction firms to minimize their environmental footprint

Emergency response protocols integrate seamlessly with facility operations, featuring rapid isolation systems and coordinated evacuation procedures. Regular safety audits and personnel training ensure that theoretical safety measures translate into practical operational excellence, maintaining the highest standards across scalable storage capacities from 1 to 100 tons.

Scalable Storage Technologies: From 1 to 100 Tons Capacity

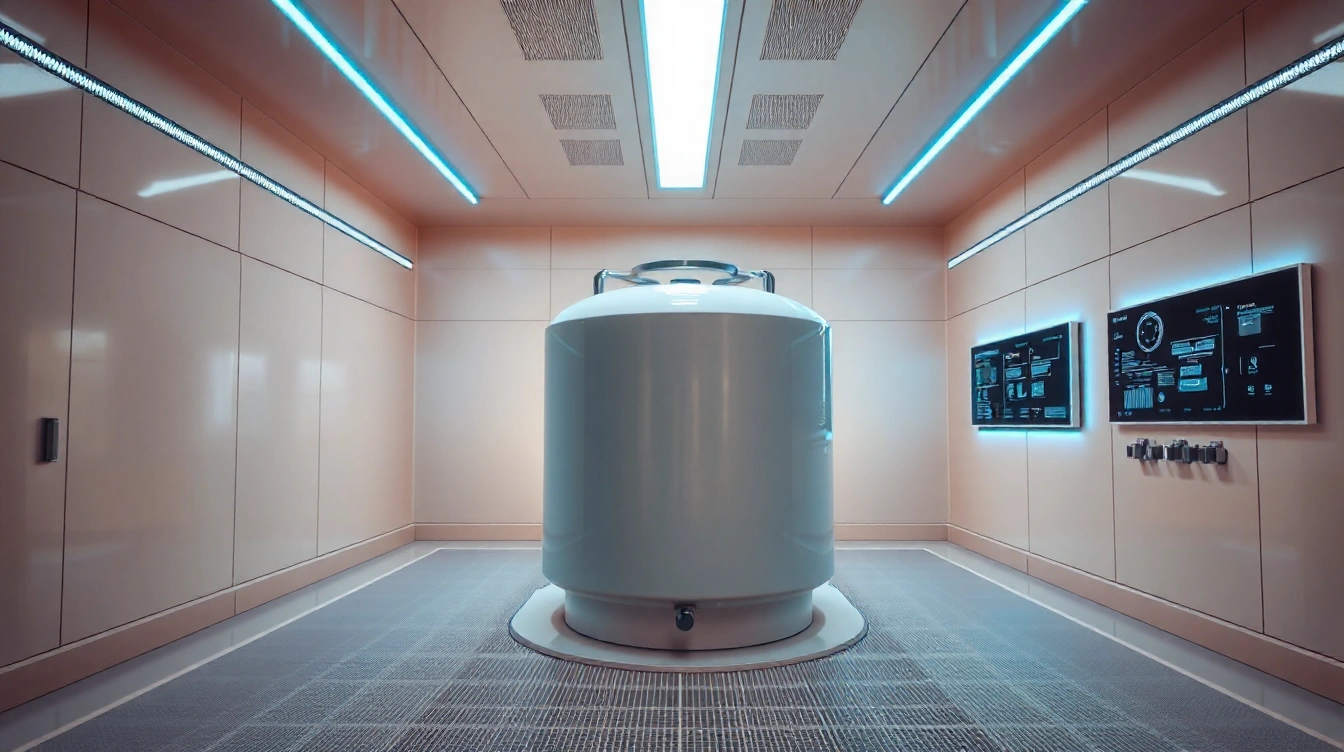

Modern hydrogen storage demands flexible solutions that can grow with industrial needs. Modular storage systems address this challenge by offering configurations ranging from single-ton installations to massive 100-ton facilities, all built on proven technological foundations.

The scalability comes from standardized storage modules that connect seamlessly. Each unit maintains independent safety protocols while contributing to the overall capacity. This approach allows companies to start with smaller installations and expand incrementally as production volumes increase, optimizing both capital expenditure and operational efficiency.

Surface footprint remains minimal regardless of scale. A 10-ton storage system occupies roughly the same ground area as a 50-ton installation, thanks to vertical stacking and underground integration capabilities. The modular architecture enables rapid deployment and reconfiguration based on evolving industrial requirements.

Configuration flexibility extends beyond capacity scaling. Systems adapt to different pressure requirements, delivery schedules, and integration needs with existing infrastructure. This adaptability proves essential for industries transitioning to hydrogen-based processes, where storage requirements often evolve during implementation phases.

Key Selection Criteria for Industrial Hydrogen Storage Systems

Choosing the right industrial hydrogen storage system requires careful evaluation of multiple technical and operational factors. The complexity of hydrogen’s unique properties demands a systematic approach to ensure safe and reliable long-term storage solutions.

- Storage capacity: Determine your current and future hydrogen volume requirements, from small-scale operations (1-5 tons) to large industrial facilities requiring 50-100 tons of storage capacity

- Safety protocols: Evaluate comprehensive safety measures including leak detection systems, pressure monitoring, emergency shutdown procedures, and compliance with international hydrogen safety standards

- Total cost ownership: Consider initial investment, operational expenses, maintenance costs, and energy consumption for compression and cooling systems over the system’s lifecycle

- Maintenance requirements: Assess routine inspection schedules, component replacement intervals, and the availability of specialized technical support for system upkeep

- Certification compliance: Ensure adherence to relevant standards such as ISO 14687, ASME codes, and local regulatory requirements for hydrogen storage installations

- Scalability potential: Select modular systems that allow capacity expansion as your hydrogen production and consumption needs grow

- System integration: Verify compatibility with existing infrastructure, production equipment, and distribution networks to minimize installation complexity

- Technical support: Partner with providers offering comprehensive engineering expertise, 24/7 monitoring capabilities, and proven track records in industrial hydrogen applications

Cost Analysis and ROI Considerations for These Storage Solutions

The economics of large-scale hydrogen storage fundamentally depend on project scale and operational duration. Initial capital expenditure for underground storage systems typically ranges from €2-4 million per ton of hydrogen capacity, while above-ground alternatives can cost significantly more due to their high-pressure requirements and extensive safety infrastructure.

Modular storage solutions demonstrate compelling cost advantages through their scalable deployment model. A 10-ton capacity system can achieve operational efficiency within 18-24 months, while larger 50-100 ton installations often reach break-even in 3-4 years thanks to economies of scale. The key economic driver lies in the reduced maintenance costs and extended operational lifespan of properly engineered systems.

Real-world examples from European industrial projects show that companies investing in proven storage technology achieve 15-25% better ROI compared to experimental solutions. This performance gap stems from reduced downtime, predictable maintenance schedules, and enhanced safety protocols that minimize insurance and regulatory compliance costs. The modular approach also enables phased investment strategies, allowing operators to expand capacity based on actual demand rather than upfront projections.

Implementation Strategies for Green Energy Projects

Successful deployment of green energy projects requires a phased approach that addresses both technical complexity and operational constraints. The implementation begins with comprehensive site assessment and infrastructure planning, ensuring that storage solutions can be seamlessly integrated into existing industrial frameworks without disrupting ongoing operations.

Technical deployment typically follows a three-stage methodology: pilot testing, scaling validation, and full operational rollout. During the initial phase, modular storage systems allow for controlled capacity expansion while maintaining safety protocols. This approach proves particularly valuable for hydrogen storage projects, where underground deployment requires precise geological analysis and rigorous safety testing before large-scale implementation.

French engineering expertise has demonstrated exceptional capability in managing complex energy transitions through proven technology demonstrators. These real-world validation projects showcase how scalable solutions can accommodate varying capacity requirements, from single-ton pilot installations to hundred-ton industrial deployments, while maintaining minimal surface footprint and operational flexibility.

Operational considerations include maintenance scheduling, monitoring system integration, and compliance with evolving safety standards. The modular design approach enables progressive capacity increases aligned with project growth phases, ensuring investment efficiency and reduced technical risk throughout the deployment lifecycle.